Innovations

THE LÜRSSEN THINK TANK

YOU CAN’T PLAN EUREKA MOMENTS. BUT YOU CAN SET THE STAGE FOR THEM.

INNOVATION WITH A PIONEERING MINDSET

Since its earliest beginnings, Lürssen has always been a pioneering shipbuilding company. From systematically optimising hull design to building the world’s first motorboat and on to today’s advancements in efficiency and sustainability – innovation is embedded in the Lürssen DNA. Accordingly, we maintain a think tank of the most forward-looking engineers and naval architects. Areas in which we have made the most progress in recent years include energy-efficient yacht design, exhaust aftertreatment and – currently – the introduction of the world’s first motor yacht powered by green hydrogen fuel cells. This last innovation, which uses bio-base methanol to produce hydrogen on board, has the potential to completely revolutionise yachting, harmonising luxury and performance with love and respect for the wellbeing of the oceans and our climate.

LÜRSSEN INNOVATIONS OVER THE YEARS.

A HISTORY OF MAKING HISTORY

GREEN HYDROGEN YACHTS

THE FUTURE OF YACHTING: ZERO GREENHOUSE GAS EMISSIONS

Awareness of the need for clean energy is growing. But in many industries, companies struggle to find mature and effective technological solutions or simply lack the vision to take decisive action. Others are constrained by the demand to deliver shareholder value. At Lürssen, we’re convinced that the superyacht industry represents a unique opportunity to make meaningful advances, which can then be applied elsewhere.

Visionary owners with a fascination for innovation and a passion for the sea are predestined to support the drive for cutting-edge clean energies. In addition, as family-owned and operated yacht-builder, Lürssen has the freedom to pursue bold visions. In a strategic partnership with maritime fuel cell expert Freudenberg, we are in the process of introducing fuel-cell powered ships.

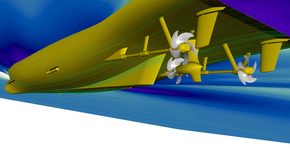

BIO-BASED METHANOL FOR FUEL CELLS

PROJECT PAXELL: COLLABORATING TO DRIVE INNOVATION

As of 2009, Lürssen has partnered with a national research project termed Pa-X-ell. Further partners include Besecke, Carnival Maritime, DLR, DNV, EPEA, Freudenberg and Meyer Werft. The collaboration partners have developed and tested a hybrid energy system with a new generation of PEM fuel cells for yachts and other passenger vessels. The pilot project uses methanol stored in tanks to produce hydrogen, which in turn feeds fuel cells that power engines and electric motors, resulting in zero emissions of nitrogen oxides, sulphur oxides, soot and CO2 (greenhouse gasses). When “green” bio-based methanol is used, the entire process becomes greenhouse gas-free. Lürssen is working to advance sustainable yachting. Take a virtual tour of the Innovation Lab and the Pa-X-ell project.

INNOVATIVE AND SUSTAINABLE: TESUMO

A TEAK ALTERNATIVE WITH SUPERIOR QUALITIES FOR SHIPDECKS

It takes innovative approaches to address sustainability issues. In 2008, Lürssen launched a project to develop an alternative to teak for shipdecks in collaboration with the University of Göttingen and the Bavarian shipdeck specialist Wolz. The result of the joint effort is Tesumo, a sustainably cultivated wood that undergoes an innovative modification process before use. Tesumo not only offers the beauty and warmth associated with teak, but actually surpasses the traditional wood of choice in many of its durability and functional properties.

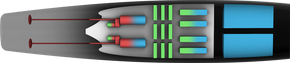

EXHAUST AFTERTREATMENT SYSTEM

We now fit the exhaust aftertreatment system on all Lürssen yachts with keels laid after 1 January 2016. Meeting regulations on limiting nitrogen oxide (NOx) emissions is a major challenge for the superyacht industry. Ships propelled by diesel engines can achieve these limits only with bulky selective catalytic reduction (SCR) systems that take up space and add weight, in turn reducing energy efficiency. Lürssen set out to develop an innovative exhaust aftertreatment system that would significantly reduce NOx emissions while also reducing space, weight, noise and vibration. We launched the R&D and implementation process in 2015 with the partners HUG Engineering and Nießing Anlagenbau. The project received funding from the German Federal Ministry for Economic Affairs and Energy. Together, we developed the concept and successfully tested it within just two years.

BETTER DATA, BETTER ENERGY EFFICIENCY

INTERCONNECTING ENERGY MANAGEMENT AND MONITORING SYSTEMS

By merging energy-related data from on-board functions and systems, we systematically enhance the transparency and energy efficiency of our vessels. Operating, monitoring and analytical functions are interconnected across system boundaries. During yacht construction, the electrical design department at Lürssen gathers and analyses more than 10,000 operational data points, spanning basic alarm information to the voltage and current of each switchboard. To best utilise all these data, we have created an automated platform to intelligently and efficiently manage energy generation, distribution and consumption on board. It features an open-interface architecture incorporating the many individual systems unique to each project.

SMART MANUFACTURE

APPLYING THE LATEST DIGITAL TECH TO TRADIONAL CUSTOM YACHT BUILDING

Digitalisation is revolutionising manufacturing, with the automotive industry leading the way. In luxury yacht construction, where tailored concepts and individual solutions are the hallmark of an outstanding shipyard, the transition to digitalised processes is not so simple. To overcome this barrier and apply digitalisation to custom-built yacht projects, Lürssen uses cutting-edge solutions like laser-marking to give each component of a vessel its own unique data matrix code. This links it to all relevant data. When scanned, the code enables our system to provide detailed information about where the piece belongs, when it needs to be installed and the quality checks required.

Are you an early adopter?

We look forward to talking about your innovative yacht